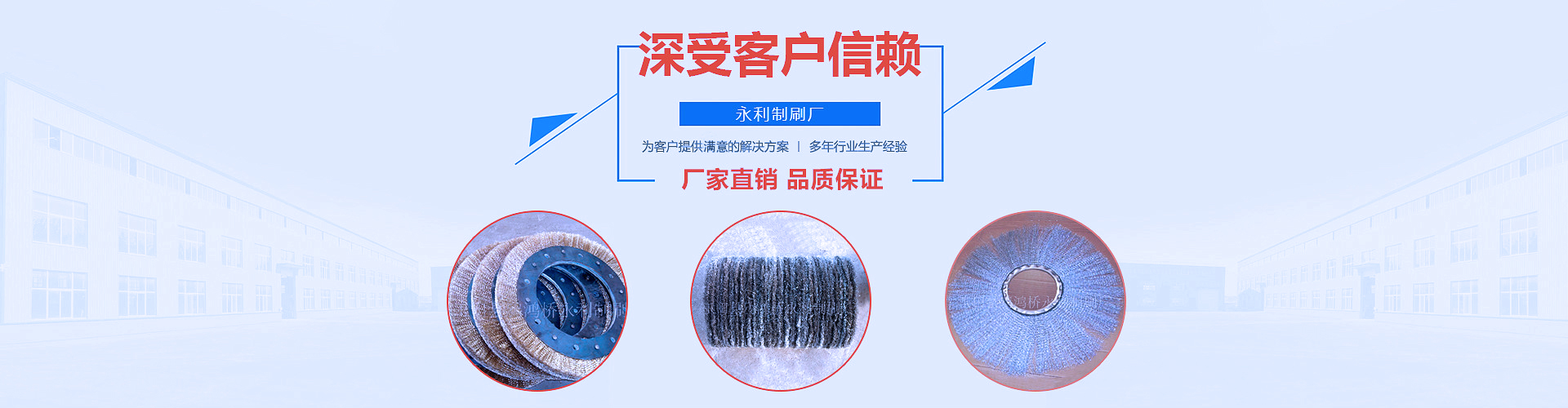

钢丝刷特别是钢丝刷辊通常应用于钢材或铝业表面处理厂,shi由一系列 的不锈钢丝刷辊安装在全自动高速运转的毛刷抛光机(刷光机)上。钢丝刷辊以与轧件运动相反的方向在板带的上下表面高速旋转刷去氧化铁皮。刷掉的氧化铁皮采用封闭循环冷却水冲洗系统冲掉。一般卷线材的使用厚度为1.09-6.35mm,钢丝刷子的更新周期为每生产2万t薄板或4万t钢卷更新一次。

Wire brushes, especially wire brush rollers, are usually used in steel or aluminium surface treatment plants. Shi is installed on a full-automatic brush polishing machine (brush polisher) with high-speed operation by a series of stainless steel wire brush rollers. The steel wire brush roll rotates at high speed on the upper and lower surfaces of the strip in the direction opposite to the movement of the rolled piece to remove the oxide scale. Scrubbed iron oxide sheet is washed out by closed circulating cooling water flushing system. Generally, the thickness of coil wire is 1.09-6.35 mm, and the renewal cycle of wire brush is 20,000 t thin plate or 40,000 t coil.